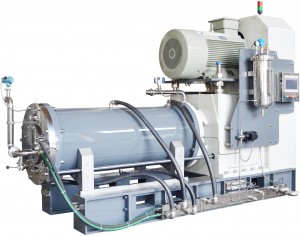

OEM/ODM Factory Paint Production Pin Type Horizontal Sand Mill For Printing Inks

Product Detail

Product Tags

With reliable high-quality process, superior reputation and excellent customer assistance, the series of items produced by our company are exported to a lot of countries and regions for OEM/ODM Factory Paint Production Pin Type Horizontal Sand Mill For Printing Inks, Should you be interested in almost any goods, remember to truly feel totally free to get in touch with us for further facts or be sure to deliver us email right, we will reply you in just 24 hrs as well as the finest quotation are going to be provided.

With reliable high-quality process, superior reputation and excellent customer assistance, the series of items produced by our company are exported to a lot of countries and regions for Horizontal Sand Mill, Horizontal Sand Mill For Inks, Pin Type Horizontal Sand Mill, Based on our guiding principle of quality is the key to development, we continually strive to exceed our customers’ expectations. As such, we sincerely invite all interested companies to contact us for future cooperation, We welcome old and new customers to hold hands together for exploring and developing; For more information, you should feel free to contact us. Thanks. Advanced equipment, strict quality control, customer-orientation service, initiative summary and improvement of defects and extensive industry experience enable us to guarantee more customer satisfaction and reputation which, in return, brings us more orders and benefits. If you are interested in any of our merchandise, remember to feel free to contact us. Inquiry or visit to our company are warmly welcome. We sincerely hope to start a win-win and friendly partnership with you. You can see more details in our website.

Turbo disperser structure

WSD large flow sand mill new type adapts new diversion trench and sand disc to achieve much higher efficient wet grinding technology. High-efficient diversion-trench grinding disc and super-big centrifugal flow turbine can be distributed in grinding chamber preferably. Centrifugal wheel is designed specially, under high line-speed, adopting centrifugal principle, centrifugal wheel can throw grinding medium and large particles to the outside of filter. This will ensure much more working life of filter and make larger particles material be grinded in chamber repeatedly. This technology solves the problem that filter is plugged up easily. Adopts centrifugal-wheel style filter to increase flow rate and to separate grinding medium safety, if for larger flow separation system, it can work in much higher efficiency.

●Disc of centrifugal grooves

●Specially designed centrifugal wheel

●Special designed large area of screen mesh

Features

●Eliminate invalid radial force of the cavity

●All material of grinding chamber is replaceable

●All easy-damaged parts can be replaced individually

●Special disc and shaft with thrust

●Special centrifugal type screen

Applications

It is applicable for automobile paint, steelroll paint, corrosion-proof paint, wood paint, screen printing ink, Gravure ink, textile pigment, TiO₂ powder, Pharmacy, Pestide etc.

![CU8X$%~Z`H5K%%K(BV@7R]B](http://img.goodao.net/longxin-global/292e0444.png)